Let's Explore Beyond

the Theory ...

Let's Explore Beyond

the Theory ...

Engineering Fluid Dynamics

I try to understand, analyze and apply my understanding of fluid behavior into real life challenges. In this way I rely on my knowledge of fluid dynamics and combining different computational and experimental tools.

Following my belief "Science for everybody", I try to follow open-source and open-access strategies in my developments and dissemination. As a very proud example, I can point at freely available codes (e.g. phasicFlowPlus) which I was involved as a core developer, the "OpenFOAM Basic Training" series which I was the main author/editor and my international corporations.

OpenFOAM® Basic Training

Computational Fluid Dynamics (CFD) is a highly specialized field that is used to simulate and analyze the behavior of fluid flows, including aerodynamics, hydrodynamics, and thermodynamics. CFD is an important tool in many industries, including aerospace, automotive, marine, oil and gas.

OpenFOAM® is an open-source CFD software package that is widely used in academic and research environments, as well as in industry. It allows users to simulate and analyze fluid flows using a range of numerical methods and modeling techniques.

For beginners, learning CFD and OpenFOAM® can be challenging, but it is also highly rewarding. By gaining an understanding of fluid dynamics and simulation techniques, you can develop new skills that are in high demand in many industries. Furthermore, as the use of CFD continues to grow, there is a growing need for engineers and scientists who have expertise in this field. The OpenFOAM Basic Training series helps you to go through the OpenFOAM® learning journey more efficiently and effectively, by providing clear explanations and practical examples that guide you through the fundamentals of CFD, the OpenFOAM® software, and its applications in different fields.

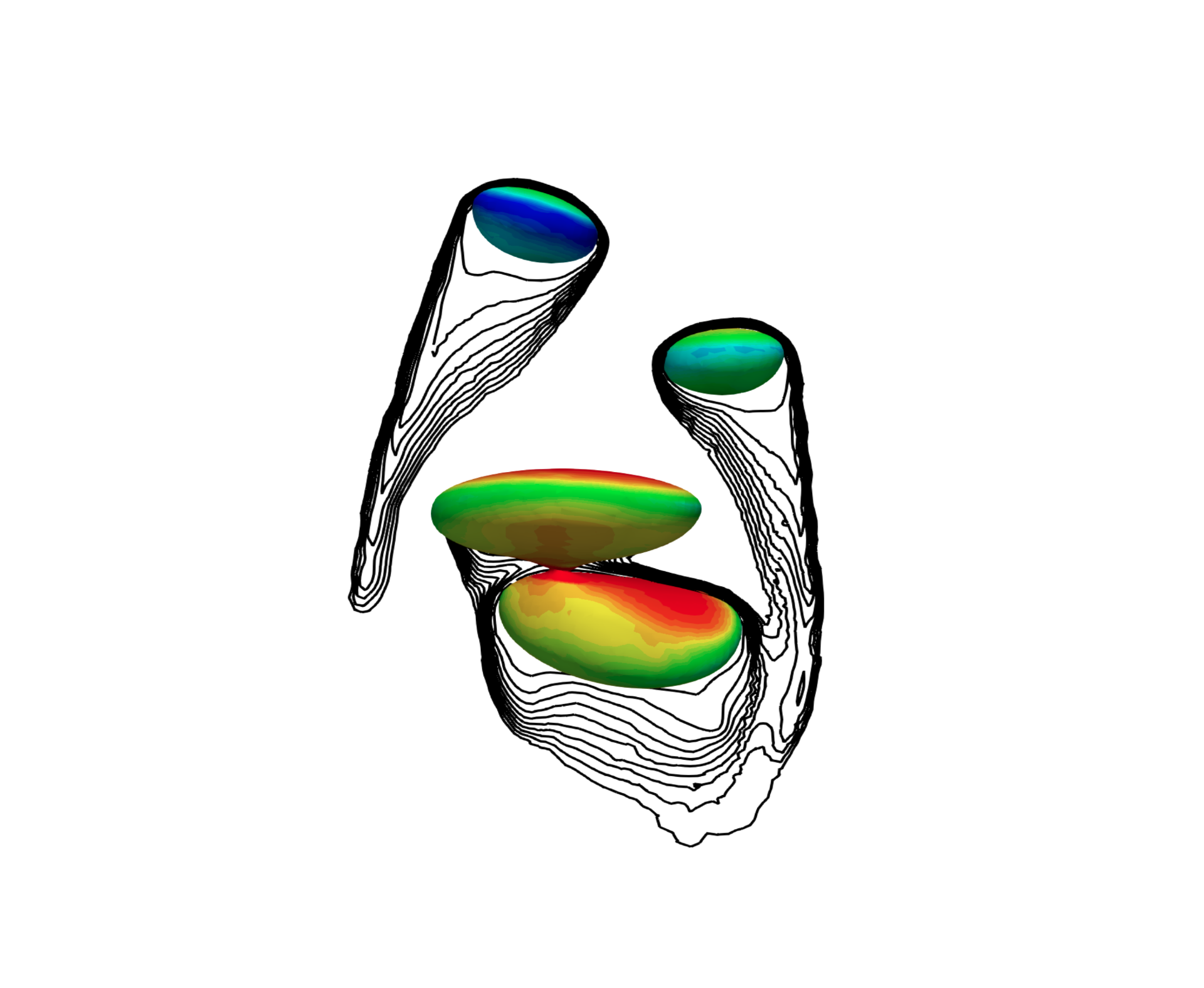

Membrane Simulation

Behavior of fluid flow around and through membrane systems can be analyzed using Computational Fluid Dynamics as a powerful tool. Membrane systems are used in a variety of applications, including water treatment, gas separation, and biomedical devices, and understanding their fluid dynamics is essential for optimizing their performance.

In a membrane system, the fluid flow characteristics can have a significant impact on its overall performance, affecting factors such as permeability, selectivity, and fouling. With CFD simulation, the behavior of fluid flow can be modeled and analyzed in detail, allowing researchers and engineers to better understand the physics of fluid-membrane interactions. Using my specialized development membraneFoam based on the OpenFOAM® platform, it is possible to create detailed numerical representation of different membrane systems and simulate fluid flows under different conditions and parameters, which can lead to improved performance, efficiency, and reliability. Details of the models and implementation can be found in this publication.

Fluid and Flow in a Single Shot

A combination of Raman and LDV allows to simultaneously gain velocity as well as chemical composition in the process stream at a specific location with a high time resolution in order to resolve turbulent and mixing phenomena. The most important aspect is to sample the light for Raman spectroscopy from the same spot at the same time as the velocity measurement is carried out. This is achieved by using the LDV laser light setup as a source for the Raman excitation. Collecting both LDV signal and Raman photons in the back scattering angle using a single collection lens, minimize the optical openings in the system to one.

Fluid composition and concentration of the components can be derived from the qualitative and quantitative analysis of the collected Raman spectrum. Generally, if no overlapping spectral features of the involved components are present, it is sufficient to evaluate the strength of a specific band in the Raman spectrum corresponding to the analyte of interest. The investigated fluid stream can be accessed optically either by using a fully transparent part of pipe (or equivalent geometry) or when working in backscattering configuration, a viewing window made of a transparent material would suffice. This enables this technology to investigate also process facilities already in operation in order to optimize process parameters. The critical point is the addition of the two parameters, composition and concentration, to the velocity information. With these, multiphase flow behavior, as well as reactive reagents, can be characterized at once by the same measurement. More information: Proof of concept, Patent 1, Patent 2.

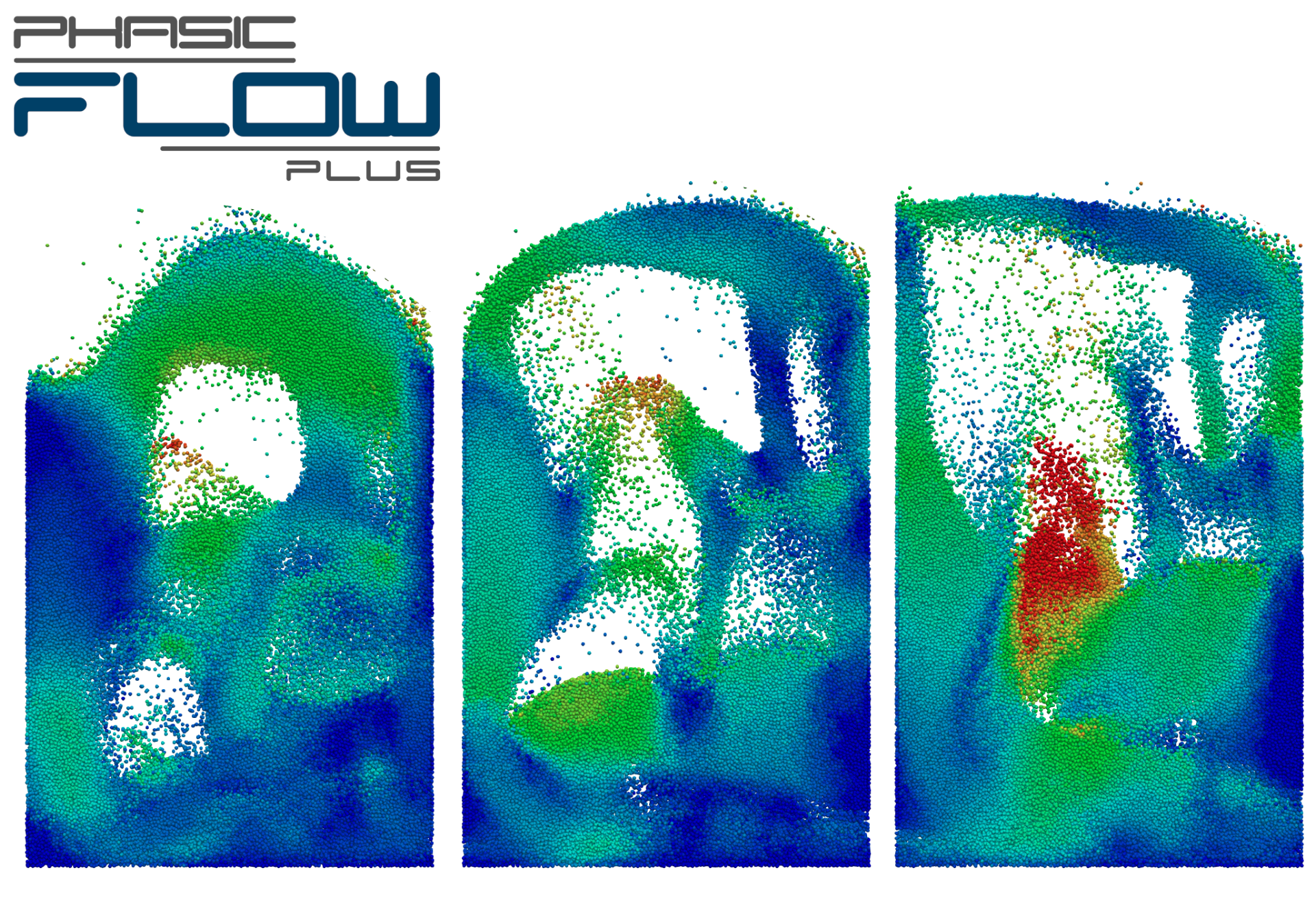

phasicFlowPlus

Computational Fluid Dynamics - Discrete Element Method (CFD-DEM) coupling is a powerful numerical technique for simulating the interaction between particles and fluid. It is commonly used in the study of multiphase flows, such as those encountered in chemical engineering, mineral processing, and Geo-sciences. CFD-DEM coupling involves simulating the motion of fluid using CFD techniques and the motion of solid particles using DEM techniques.

Parallel computing platforms are widely used in scientific and engineering simulations to reduce the computational time required for large-scale simulations. In CFD-DEM coupling, parallel computing platforms are particularly useful, as they allow the simulation of large numbers of particles and complex flow geometries (e.g. engineering problems).

phasicFlow is a multi-parallel platform DEM code which offers massive parallelization of particle simulations. Combining phasicFlow with OpenFOAM®, allows for a faster/more efficient computation of the fluid-particle problems, enabling researchers to investigate complex systems and optimize their design/process in a more efficient manner. I had the pleasure of being a part of the core developers team, mainly focusing on CFD and coupling sections. Feel free to download and try the open-source CFD-DEM coupling: phasicFlowPlus.

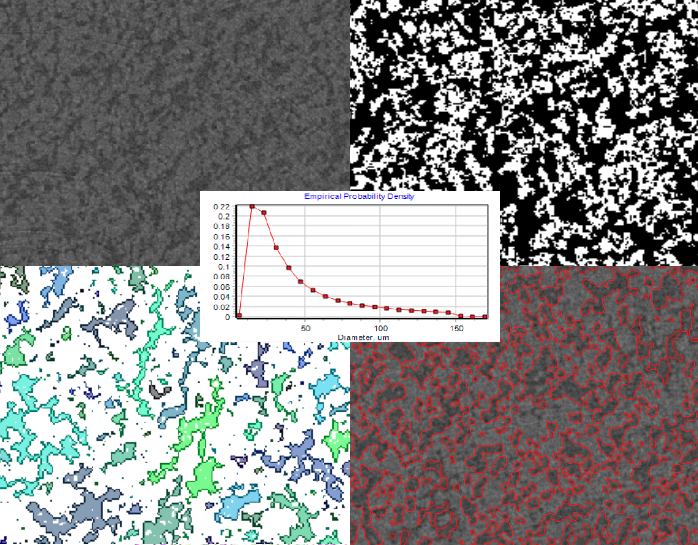

Porous Structure Investigation

Porous media holds great importance in the field of fluid dynamics. These materials, characterized by interconnected pores and void spaces, play a critical role in various fluid-related domains. Understanding and studying porous media is essential for applications such as groundwater flow, oil and gas reservoir engineering, filtration systems, and heat transfer processes. However, existing methods for investigating porosity based on physical property measurements are highly complex, expensive and often requiring harsh experimental conditions. Furthermore, these methods are unable to provide accurate pore size distribution information. Similarly, modern optical measuring techniques are not universally applicable and often require significant modifications for different specimens.

To address these challenges, a new approach to streamline the direct measurement of porosity in a specimen using a series of its images was developed. This proposed method involves several steps, including image denoising, separating aggregates, measuring microstructural elements, and conducting mathematical analysis on the acquired data. The reliability of this technique has been demonstrated through numerical experiments using CT images of a porous ceramic sample. These experiments suggest that the developed method holds promise in accurately assessing porosity in a more efficient and reliable manner. You can read more about this new technique in this article.

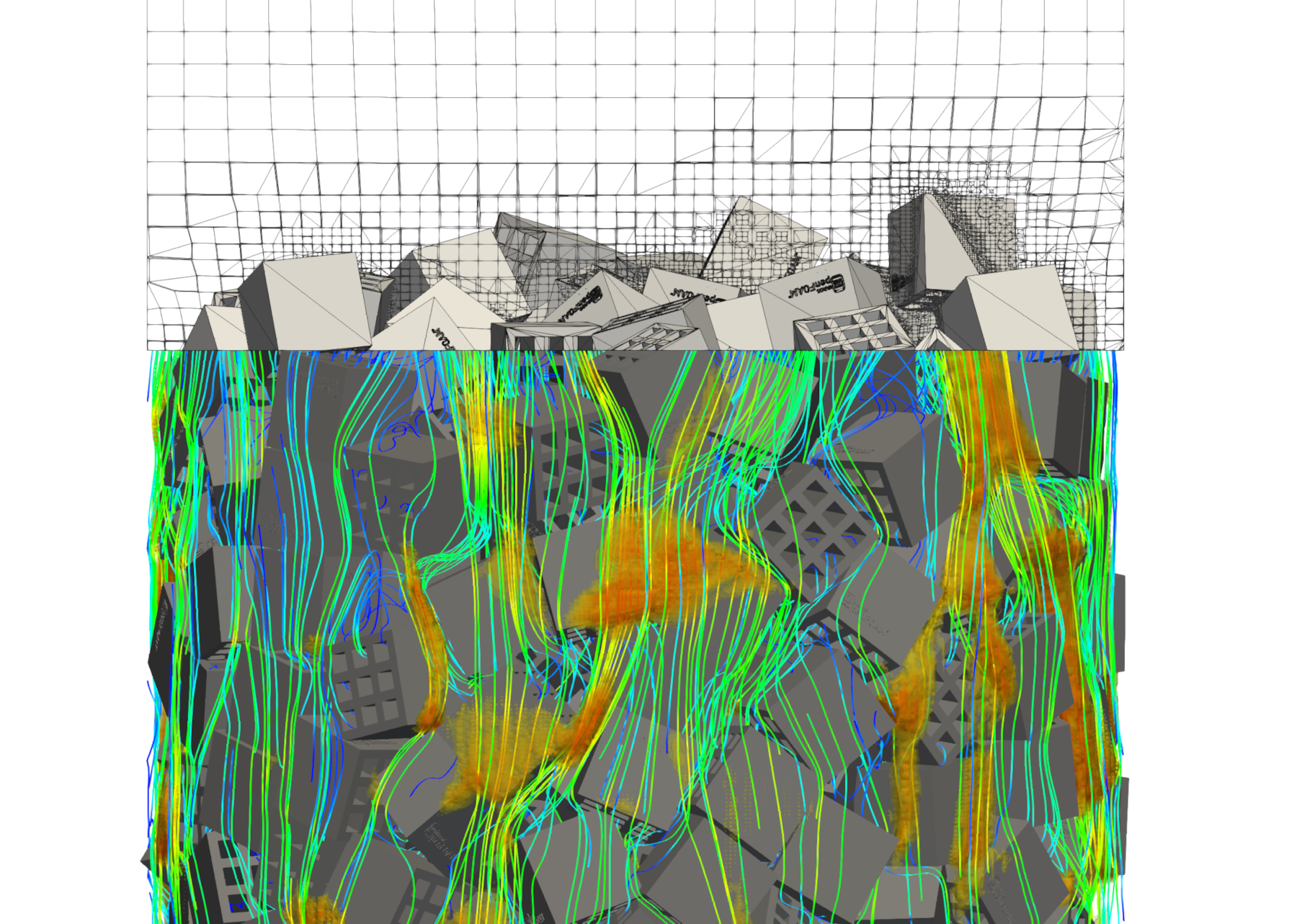

Adsorption and Packed Beds

Packed beds are commonly used in the separation and purification of chemicals. they consist of a column filled with porous materials, such as activated carbon, zeolites, or silica gels, where a fluid containing adsorbate molecules is passed through the bed. The adsorbent material selectively binds to the adsorbate, effectively separating it from the fluid.

By using CFD simulation, researchers can investigate the behavior of fluid flows and the distribution of the adsorbate molecules within the packed bed. This enables them to optimize the design of the packed bed, the choice of adsorbent material, and the operating conditions for achieving maximum adsorption efficiency.

Utilizing the CFD and DEM tools, adsorpFoam (developed by me as a custom tool based on OpenFOAM for adsorption simulation) and phasicFlow, allows for the creation of detailed geometries and numerical models of packed beds and the flow of fluids through them, which can then be used to study and optimize the adsorption process. The simulation can take into account factors such as fluid velocity, temperature, and pressure, as well as the physical properties of the adsorbent material and adsorbate molecules. For more details check this publication.

Liquid-Liquid Extractor

Liquid-liquid-extraction based sample conditioning is applied in analytical and micro-chemical engineering for the purification and analysis of fine organic compounds. It is widely used in key industries.

Extraction is a two-step process - mixing and separation - which can be demanding and inefficient in case of non-automated or batch handling. My colleagues and I at TU Wien have developed a device that makes liquid-liquid separation much more efficient and convenient.

This novel two-in-one micro-device allows for extraction in a continuous, automated, remotely controlled process. The proposed multi-stage extractor achieves advanced mixing and separation quality by controlling intensity and back mixing. The compact combined design of reduced mechanical parts minimizes dead volume and required space, increases separation efficiency, and makes operation and maintenance more time-, cost and space efficient.

Testing several prototypes of the extractor have proven the technology's functionality and advantages in continuous automated extraction in waste water analysis. This new design can improve extraction processes in analytical laboratories or be scaled up for industries such as pharmaceuticals, food, cosmetics, biochemistry, hydro-metallurgy, paper and oil industry. More information can be found in this patent.